European-Standard-1219522001-Ratchet-Strap-Assembly

Label & Marking requirements BSEN 12195-2:2001

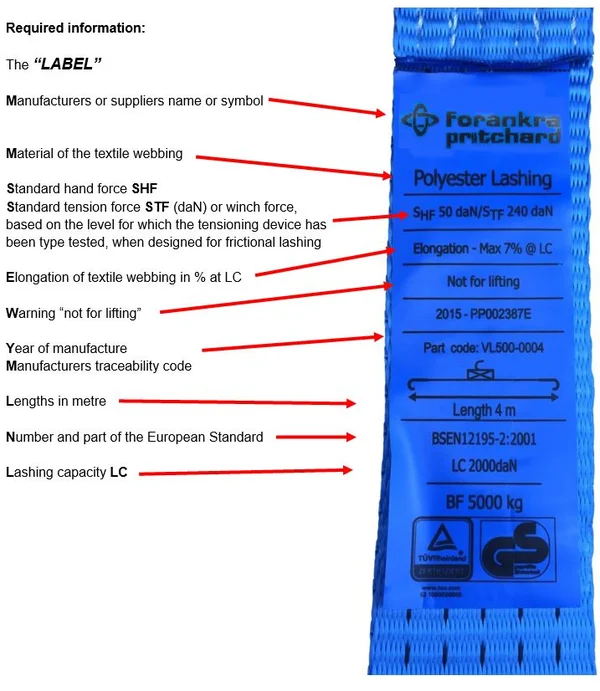

The European standard for Load Restraint Assemblies on Road Vehicles: “Part 2 – Web lashing made from manmade fibres” outlines the requirements for manufactures. Forankra UK supply ratchet lashings and straps that comply and exceed the European Standard. Part of the standard gives the requirement for the marking of the ratchet lashing. This is undertaken by sewing into the strap a label, made from PVC and colour coded to the type of webbing used in the assembly.

Section 8 of the standard outlines the minimum requirement and is entitled:

“MARKING”

The marking shall be according to EN 292-2:1991, clause 5.4. Each complete web lashing, if it is intended that parts be separable, shall be marked with the following information if applicable on a label.

End fittings, tensioning devices, tension retaining devices and tension indicators of LC ≥ 5 kN shall be marked with the manufacturers or suppliers name or symbol.

The value of LC shall be marked on parts with LC ≥ 5 kN in kN, on parts with LC < 5 kN in daN

Labels shall have the following colours:

Blue = PES webbing, Green = PA webbing or Brown = PP webbing

Compliance

To comply with the European Standard, ratchet strap assemblies should have a required label sewn into the stitch pattern. The end fittings and tensioning device should be marked as per the standard requirement. As a leading manufacturer Forankra strives to ensure that all requirements are fulfilled.

There are demands within the industry to show the overall break force for lashings. The standard makes no requirement to state the BF on the label. However, it has become the industry norm to indicate the Break Force BF. The BF can be any force above 2 x LC as explained below. For example, you can mark the assembly as LC 2000 daN and show the break force as 7000kg, if when tested that’s where it breaks. The extract from the standard below explains.

Section 6.4: Testing of the complete web lashing – once loaded and held to 1.25 x LC, released and checked. Then retested, the lashing must withstand at least 2 x LC. The following note then states that “the breaking force may then be determined” This then relates to section 3 Terms and definitions 3.14: breaking force BF is the “maximum force that the web lashing withstands when tested”.

There is NO direct relationship or ratio factor between the LC and BF .